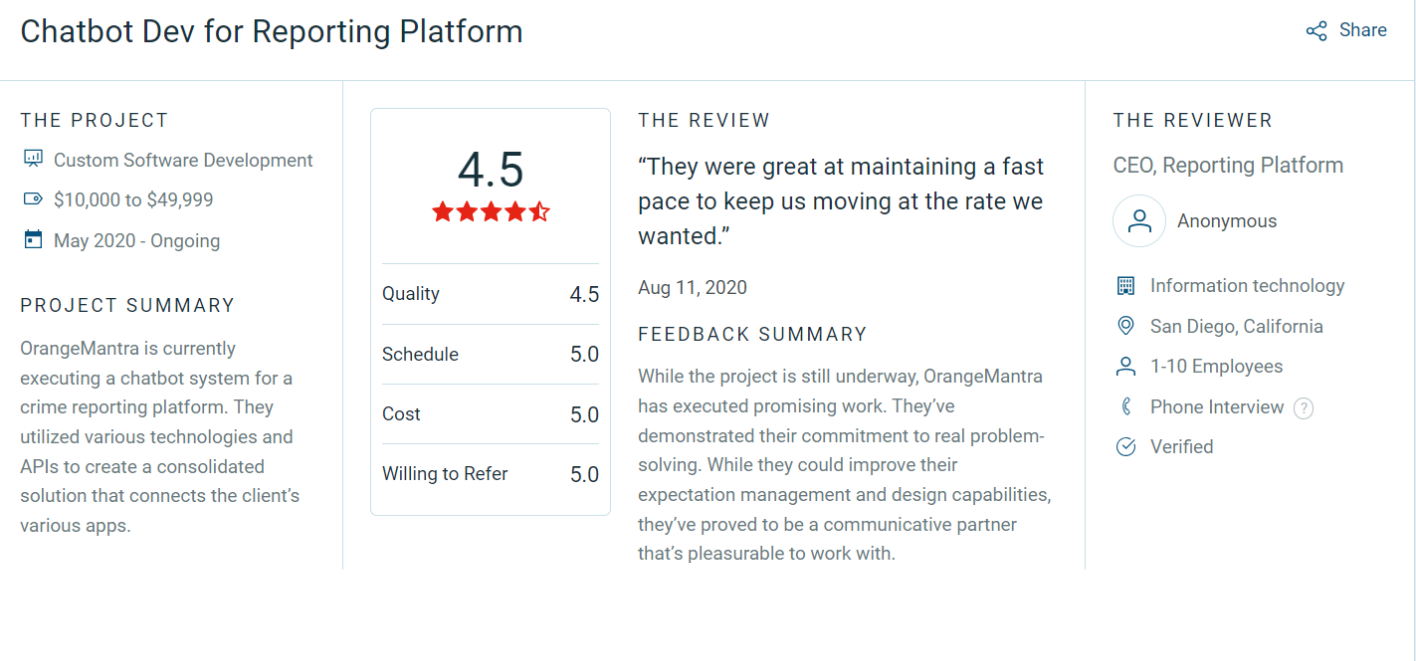

AI Powered Visual Inspection Services for Smarter Manufacturing Starts

Make your quality checks faster, sharper, and more reliable. Our AI powered visual inspection services help you spot defects early, reduce waste, and improve product quality across every stage of production.

Detect defects instantly

Detect defects instantly  Cut inspection costs

Cut inspection costs  Boost production accuracy

Boost production accuracy Reduce human errors

Reduce human errors

Python

Python TensorFlow

TensorFlow OpenCV

OpenCV FastAPI

FastAPI Labelbox

Labelbox Microsoft Azure AI

Microsoft Azure AI REST APIs

REST APIs  Power BI

Power BI  Grafana

Grafana Tableau

Tableau