In the last few years, there has been a dramatic shift in industries due to the arrival of various cutting-edge Tech Trends. Several big and small businesses have been embracing these changes while new technologies are emerging in succession.

This year holds a plethora of trends and technologies set to revolutionize industrial organizations by improving operations and streamlining efficiencies. 2023 marks the dawn of digital transformation for industries, with IT and OT combining forces to become a unified force.

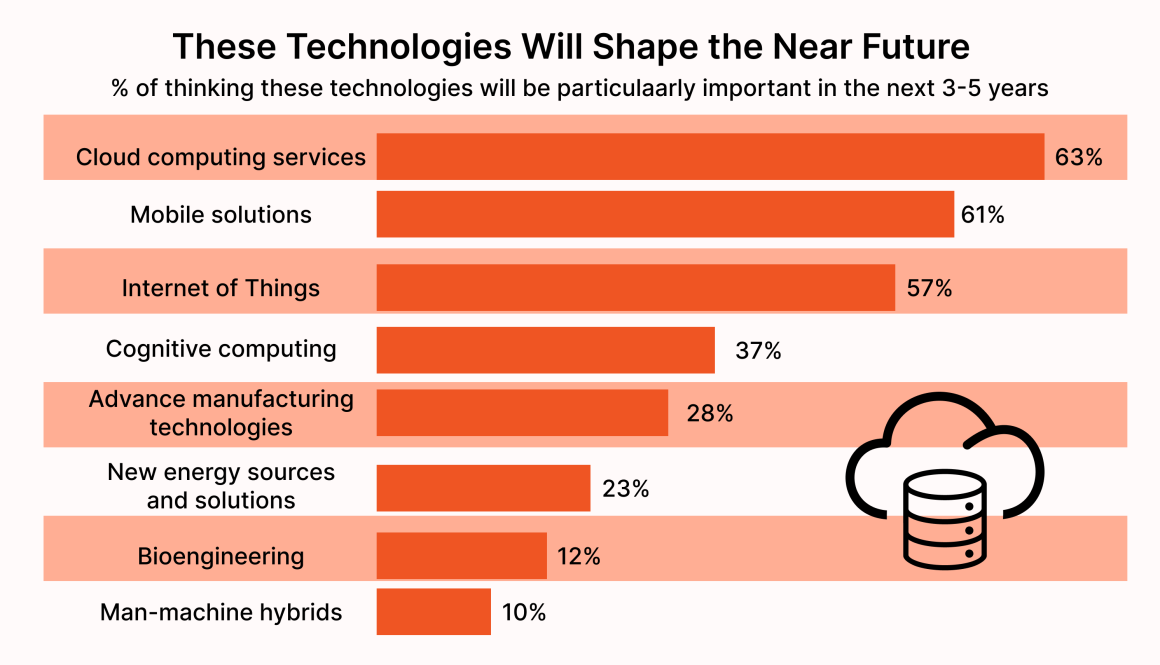

Are you wondering how will tech trends change in the future? Let’s explore the primary technology trends that will further reshape the industrial landscape in the coming years.

Digital Twinning: More assets will have digital twins

Being top tech trends in 2023, Digital twins refer to the virtual models that replicate the physical assets of an organization. They contain an archive of asset information, such as its drawings, engineering analysis, bills of material, manufacturing data, and historical operational information.

Industrial manufacturing will be increasingly embracing this technology to collect asset intelligence, enhance product visibility, facilitate collaboration, and benchmark the asset performance. Specifically, digital twins can assist industrial organizations in the following ways:

- Leverage asset knowledge to minimize operational complexity and maximize its performance

- Get a holistic perspective of the asset to manage its risk and safety more effectively

- Collect real-time data related to the asset for accelerating and improving operational decision-making

- Facilitate asset monitoring, failure diagnostics, and predictive analytics for minimizing downtime

Technologies like artificial intelligence (AI), machine learning (ML), Big Data and Analytics, and rules-based logic are the lifeline of digital twinning. Even though this might spell considerable tech investment for enterprises, they will be eager to opt for digital twinning of their major assets.

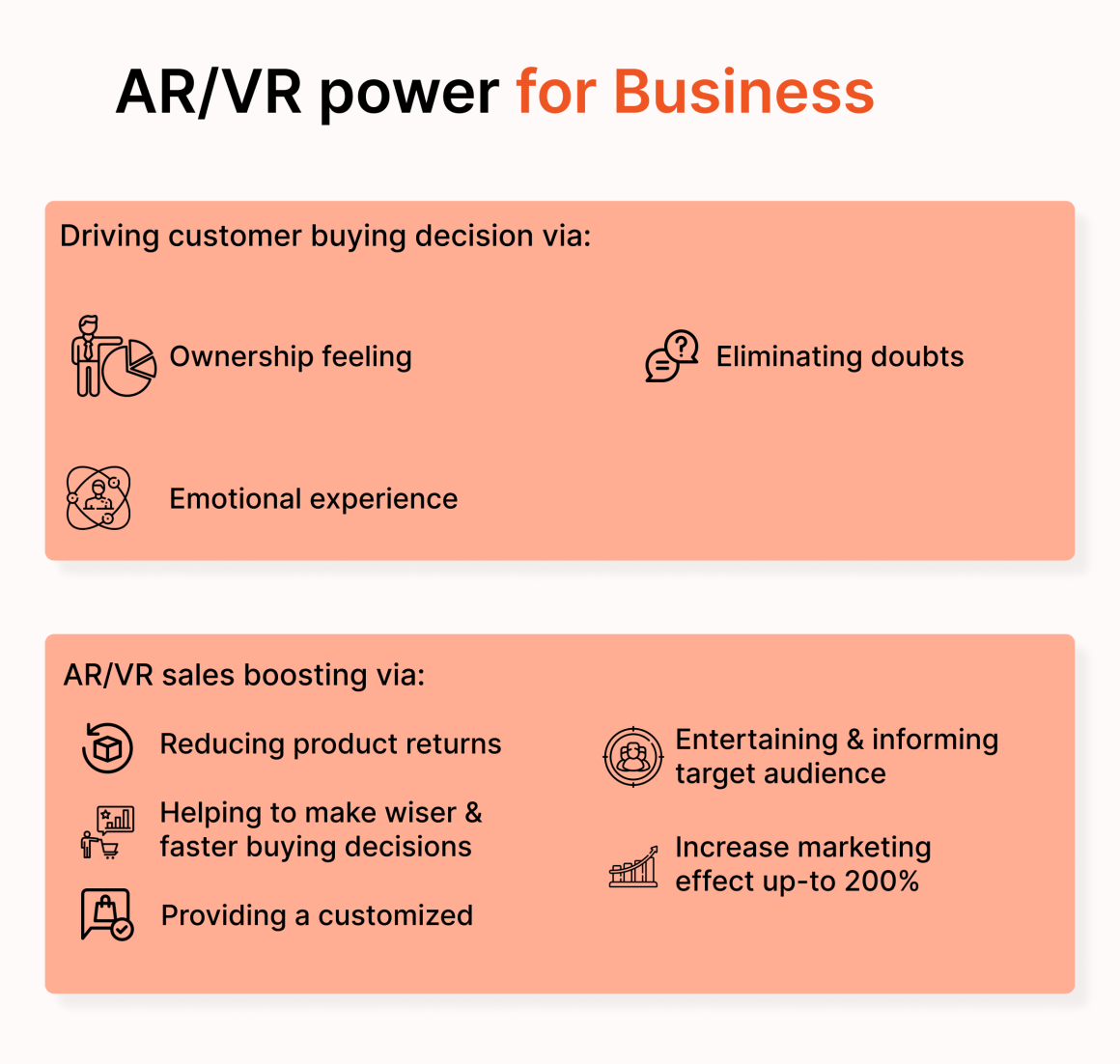

Augmented Reality: Improved Knowledge Transfer

Intra-organizational knowledge transfer is one of the biggest challenges in industrial enterprises with complex processes and operations. The challenge will be considerably addressed by deploying AR-based applications that can serve interactive experiences which overlay digital information over the real scenarios.

Here are the ways in which AR can improve knowledge transfer within industries:

- Provides clear and detailed workflows and procedures for faster throughput from the learners

- Incorporates automated inspection within the application for better learning and quality control on implementation

- Reduces rework as the learners will be able to share their video feed directly with a mentor

- As the AR devices are “intelligent”, they display only the data required for the operation at hand

- Knowledge sharing via AR is accomplished with the help of video-see-through technology as used in mobile/tablet apps and wearable apps that run on smart wearables.

Being one of the top emerging tech trends, it allows businesses to transform online customer experience with more interactive environments.

Virtual Reality: Training and Simulation Will Be a Norm

Besides knowledge sharing with the new resources is important for any industrial organization, so is training of the new as well as existing workforce. In 2023, the tech trend of using VR for training and simulation will surge ahead as more and more players will be keen to train their workforce via closer-to-life, simulative training sessions.

Some exclusive benefits of leveraging VR for training include:

- Provides a highly realistic, virtual environment with real-time, contextualized data overlaid

- Facilitates extensive familiarity with the equipment as well as operational, maintenance, and risk-handling procedures

- Enables the creation of near-limitless training scenarios without disrupting the regular operations

- Offers a repeatable, low-stress learning environment to the learners so that they can master their skills eventually.

Training and simulation based on VR technology is backed by sensor-powered devices such as eye- and head-tracking wearables. These are run with VR-based applications that make the devices capable of synchronizing the virtual display with the wearer’s motion.

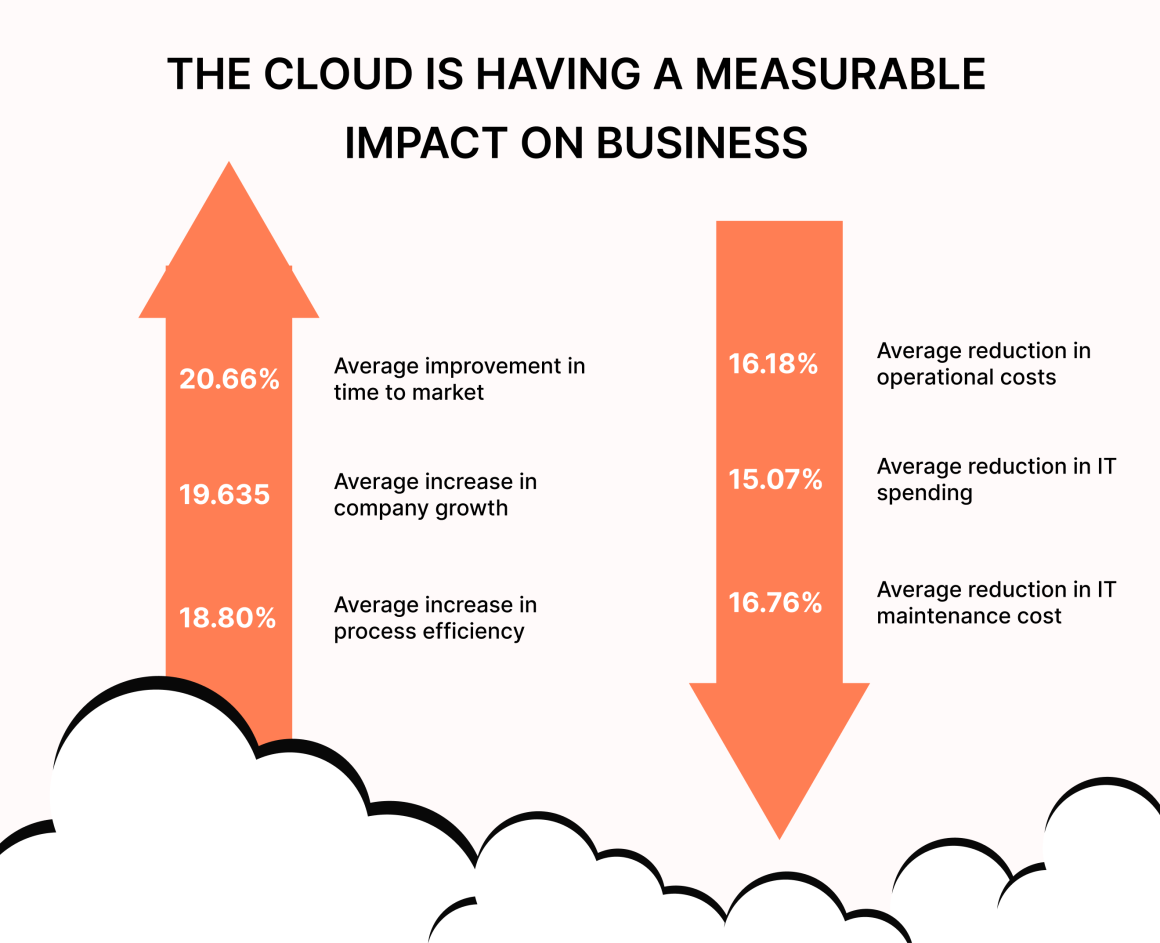

Edge-to-Cloud: Win the Industrial Game

As the boundaries between IT and OT are gradually merging, manufacturers need to embrace the application-to-application approach while deploying their computing resources. Utilizing a combination of cloud and edge solutions becomes the key to distribution of computing resources more successfully and broadly for industrial organizations.

Here are some reasons that the edge-to-cloud combination scores as a winner:

- Provides the appropriate personnel with actionable information for taking real-time business decisions

- Delivers industrial-grade availability of crucial data and information over the cloud

- Enables a reliable identification of process-related and operational inefficiencies

- Assists the business in pinpointing the potential production, safety-related, or environmental issues

The adoption of edge and cloud approach simultaneously entails the deployment of edge devices with edge servers, embedded analytics, machine learning, artificial intelligence, and cloud infrastructure. Since there are multiple technologies involved, this will be a complex process for business enterprises. You might also like to explore how cloud computing is evolving at a dizzying pace.

Cybersecurity: Address the Security Concerns

With the number of cyber threats growing massively, security becomes a major concern for enterprises. In 2023, businesses will focus on converging their IT and OT cybersecurity efforts to address the security gaps and challenges that seem to have increased with the growing number of cyber-attacks and data loss incidents in the previous year.

Moving on to a converged IT/OT cyber security model will bring the following benefits for the organizations:

- Ensures a greater consistency in the security levels across the entire organization

- Allows the closure of gaps in the existing programs and helps defend against new challenges as well

- Brings extensive boost in productivity as the threat of security will be resolved for the business

- Reduces the chances of security incidents, both physical and virtual, within the organization

Being current technology trends, IT and OT are two different world and securing them as a cohesive unit can be a challenge. While IT security is about securing business data and information, OT security is about securing assets and infrastructure.So, enterprises would need to find a digital transformation partner that can deliver complete cyber security solutions to handle both aspects.

Internet Of Things: Connected Devices for Operational Efficiency

Being one of the latest technology trends, IoT is quickly becoming a game-changer in the way businesses and organizations operate. By connecting physical objects to the internet, IoT enables businesses to monitor, collect, and analyze data from their products, assets, and even the environment in real-time. This opens a world of possibilities that were previously unimaginable.

- Improved efficiency and cost savings by reducing the time and resources spent on manual processes.

- Automation to streamlining operations with the connected and controlled devices remotely.

- Save time, reduce overhead costs, and increase accuracy.

- Valuable insights into customer behavior and preferences through connected devices.

- Enabling target marketing with precise customer insights.

On the organizational level, IoT applications can be used for predictive maintenance and to better monitor production processes. For example, industrial operations can track machine performance, detect problems before they arise, and alert technicians when repairs or maintenance is necessary.

With the ability to better understand their environment, organizations can take more effective action to improve safety, security, and sustainability. The potential of IoT technology is far-reaching and has already been embraced by numerous industries across the globe.

From smart homes to transportation systems and healthcare facilities, organizations are increasingly investing in IoT solutions to make operations more efficient and maximize their impact.

Big Data & Analytics: Leveraging Data to Enhance Operations

If you are wondering what technology trends in are 2023, you must not miss out on big data and analytics. They have revolutionized the way businesses operate. They enable organizations to harness the massive amounts of data available from digital sources. And enabling them to understand customer needs, identify patterns and trends, and make better decisions.

Here are different ways Big Data & Analytics can benefit businesses:

- Understand customer preferences, make predictions about future events, and develop strategies for growth.

- Gain insights into their customers’ behavior and develop more effective marketing campaigns.

- Improve operational efficiency and predict demand.

- Develop predictive maintenance models that identify possible problems before they happen.

- These insights allow companies to save money and resources by proactively addressing issues before they become more costly.

Moreover, Big data and analytics also provide companies with an edge when it comes to competition. By providing up-to-date information on customers’ interests and preferences, organizations can develop better products and services that better meet the needs of their customers.

Furthermore, big data and analytics can provide a better understanding of customer segmentation and help organizations target specific market segments with tailored offers and promotions. Finally, big data and analytics are invaluable tools for businesses in terms of risk management.

By combining internal data with external sources, companies can assess and manage risk in a timely manner, allowing them to mitigate potential losses before they occur. Overall, the potential for big data and analytics in business is immense. And allowing organizations to better understand their customers, anticipate future needs, increase operational efficiency, and improve their competitive advantage.

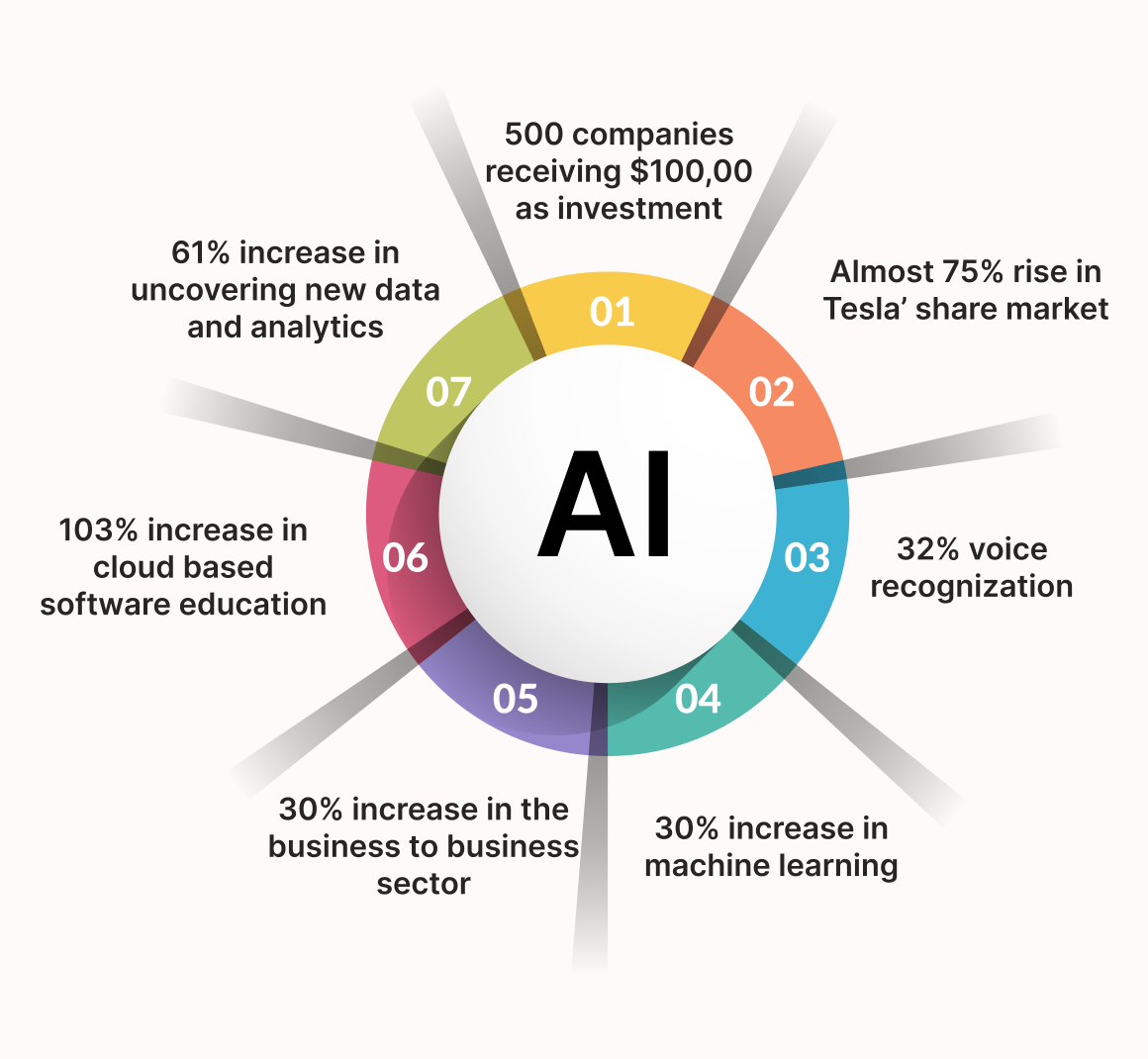

AI & ML: Improved Decision Making & Data Processing

The inception of AI and ML has revolutionized the way businesses and organizations operate. By leveraging these technologies, businesses and organizations can gain insights that drive decision making, automate mundane tasks, and develop new services and products.

These technologies are becoming essential technology trends in 2023 for companies looking to remain competitive in a rapidly changing business landscape.

Here are some ways AI & ML can benefit businesses:

- Process large datasets faster than ever before, allowing for more accurate predictions and forecasts.

- Identify patterns and trends in data, AI can be used to provide insights into customer behavior and market trends

- Help organizations make informed decisions quickly.

- Automate mundane tasks, freeing up employees’ time to focus on more complex tasks.

- Streamline customer service operations by responding to customer inquiries and automatically resolving simple requests.

ML is being used to build predictive models that allow organizations to identify customer preferences, generate targeted content, and anticipate customer needs. By understanding customer behaviors, ML can be used to develop tailored marketing campaigns.

Overall, it increases conversions and optimize the customer experience. ML is also being used in computer vision applications such as facial recognition, enabling companies to offer personalized services and improve security.

Succinctly, AI and ML are powerful tools that are reshaping the future of IT and business. They are helping companies increase efficiency, improve customer service, and create new products and services that give them a competitive advantage. Undoubtedly, AI is the future of technology, allowing businesses to leverage its power to remain competitive in the marketplace.

IT as a Service: Better Storage & Server Capacity

In today’s digital age, IT as a Service (ITaaS) is becoming increasingly important to businesses. ITaaS is a delivery model for IT services where businesses can access a range of IT resources such as servers, applications, and storage on a subscription basis.

Being the future of IT, it enables businesses to access the technology they need without having to invest in expensive hardware or software licenses. By leveraging the scalability of cloud computing, ITaaS allows businesses to respond quickly to changing needs, adapting their IT environment to fit their business goals.

This agility makes it easier for companies to create new products, launch new services, and adjust quickly to changing market conditions. In addition, ITaaS offers scalability and reliability, allowing businesses to choose the level of service they need and ensure that their IT environment is always available.

- Reduces upfront cost of hardware and software licenses.

- Helps to reduce long-term IT costs with scalability and flexibility.

- Provides access to the latest technology without investing in upgrades.

- Gives organizations access to skilled personnel on an as-needed basis.

- Offers secure data storage and access to services from anywhere, anytime.

- Allows organizations to better manage their IT resources and focus on core business processes.

- Gives organizations the opportunity to leverage the expertise of specialized IT providers.

Furthermore, with ITaaS, businesses can reduce costs by eliminating the need to purchase and maintain in-house IT infrastructure. ITaaS provides access to the latest technology without having to invest in expensive hardware or software upgrades. This helps businesses save money on upfront capital costs and ongoing maintenance costs.

Overall, IT as a Service is transforming how businesses access and use IT resources, while catching up with top technology trends in 2023. By providing cost savings, agility, scalability, and reliability, ITaaS is helping businesses become more competitive and successful in today’s digital economy.

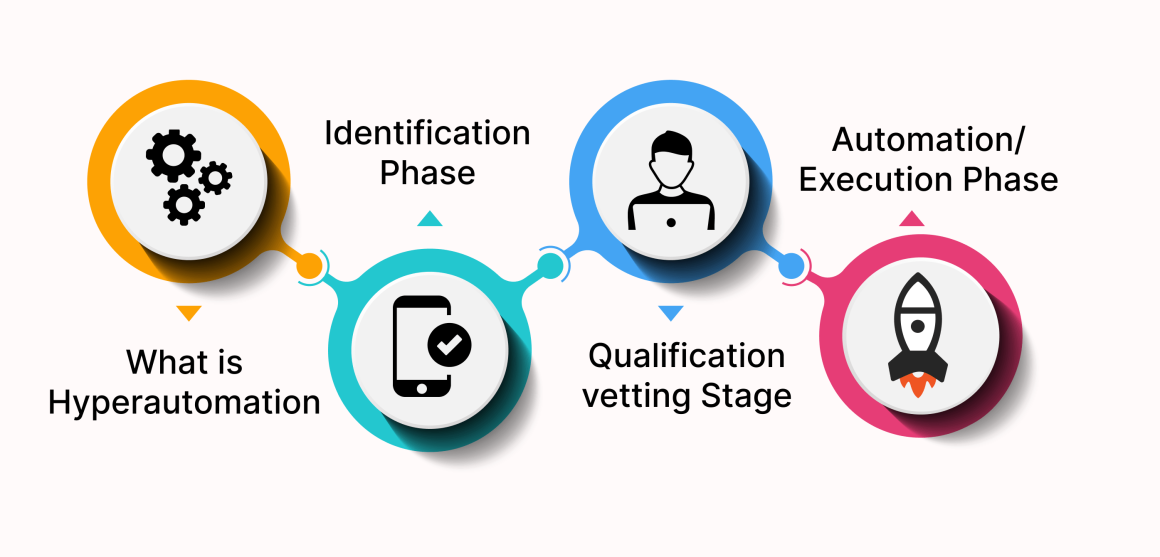

Hyper Automation & Virtualization: Enhancing Processes & Operations

Hyper automation and virtualization are two of the most important trends reshaping the future of IT and business. It is the process of automating all aspects of a business, from operations to customer service.

By leveraging advanced technologies such as artificial intelligence (AI) and machine learning (ML), businesses can significantly reduce costs, increase efficiency, and improve customer service. Virtualization is the process of creating virtual versions of physical resources.

This includes everything from software applications to storage solutions. By utilizing virtualization, companies can save money and time, increase productivity, and reduce energy consumption. It also provides flexibility to scale up or down depending on the business needs.

- Increases operational efficiency by streamlining manual processes

- Automates IT operations and reduces human intervention

- Enables faster response times for customers

- Enhances data security by leveraging cloud computing

- Reduces infrastructure costs with virtualization

- Allows for the automation of repetitive tasks, freeing up resources for other initiatives

- Improves employee productivity by reducing manual tasks

Combining hyper automation and virtualization will allow businesses to optimize their resources and operations. It will provide greater flexibility for businesses to quickly adjust to changing market conditions and customer needs.

In addition, it can help businesses take advantage of cutting-edge technologies such as AI and ML to improve customer experience, increase efficiency, and reduce costs. Overall, hyper automation and virtualization are key trends that are reshaping the future of IT and business. By leveraging these technologies, businesses can gain a competitive edge in their respective markets.

Hybrid Infrastructure: Boosting Remote Work Culture

As one of latest techn trends in 2023, Hybrid infrastructure is a combination of both traditional on-premise and cloud-based infrastructure technologies. It offers businesses a way to transition to the cloud while still leveraging the existing hardware and software investments they have made in their on-premise infrastructure.

Moreover, it offers organizations the ability to quickly scale up or down based on their needs. It can also help reduce costs and improve overall performance by taking advantage of the best features of both on-premise and cloud solutions.

By leveraging hybrid infrastructure, organizations can gain greater control over their data, applications, and services while still enjoying the benefits of cloud computing. With hybrid infrastructure, companies can take advantage of both on-premise and cloud-based resources as well as the elasticity of the cloud.

- Combines on-premises and cloud-based IT infrastructure for an optimized and flexible system.

- Enables organizations to adapt to changing business needs, quickly scaling up and down depending on the requirements.

- Improves operational efficiency by running critical applications locally or in the cloud, depending on the performance, security, or cost requirements.

- Automates processes across cloud platforms, reducing manual workloads and ensuring smooth operations.

- Increases IT agility with a single, integrated platform that simplifies the management of different environments.

This helps ensure that their applications remain agile and responsive to changing needs. Additionally, hybrid infrastructure allows for the flexibility of workloads between on-premise and cloud environments. Thus, allowing organizations to maximize their investments and respond quickly to changing business demands.

Hybrid infrastructure is becoming increasingly popular as businesses look for ways to become more efficient and cost effective.

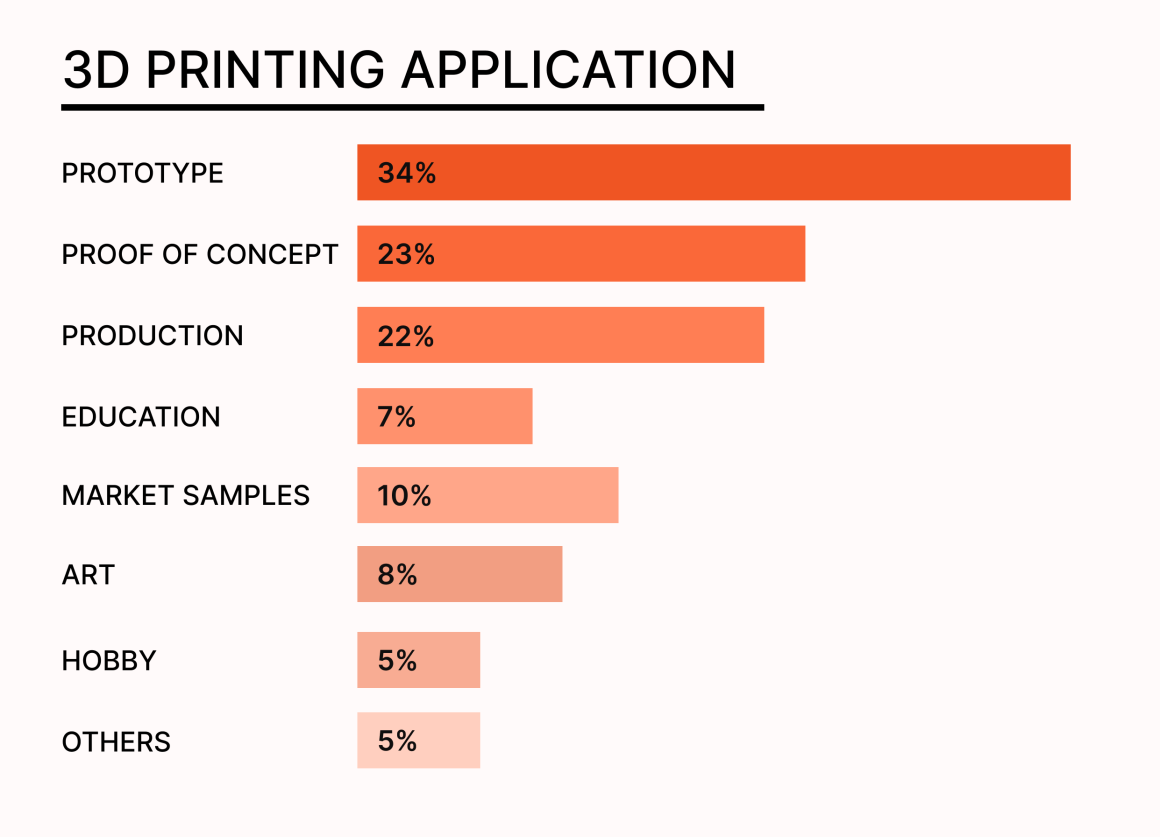

3D Printing: Faster & Seamless Prototyping

As top tech trends in 2023, 3D printing has become a major disruptive force in the manufacturing industry, allowing for the development of unique products and parts with unprecedented speed and accuracy. It is rapidly becoming an integral part of many industries and businesses, from automotive to aerospace and medical devices.

3D printing has opened opportunities for entrepreneurs and innovators to create custom, one-of-a-kind products with minimal time and effort. The technology works by using digital designs and then transforming them into physical three-dimensional objects through the additive manufacturing process.

- 3D printing technology allows for the creation of complex parts and products with detailed design and accuracy.

- It reduces time to market, as this printing shortens the design, prototyping and manufacturing process.

- It enables the production of customized parts and products, eliminating the need to produce multiple variations of a product.

- By using 3D printing, the need for large production runs is eliminated and capital costs are significantly reduced.

- 3D printing leads to cost savings in manufacturing, as expensive tooling is not required.

- The materials used in 3D printing can be more eco-friendly than those used in traditional manufacturing methods.

- It can also provide improved product performance, due to its ability to manufacture objects with unique properties and features.

Unlike traditional machining processes that involve cutting away material, 3D printing builds layer upon layer of material to form an object. Moreover, this technology allows for complex geometries that would be impossible with traditional methods, as well as reducing production costs and improving production times.

3D printing offers many advantages to manufacturers, such as faster prototyping, cost savings, reduced waste, and quicker production turnaround times. It also enables companies to quickly produce custom parts or components, allowing them to respond quickly to customer demand.

Overall, 3D printing can also reduce material costs by eliminating the need for tooling and providing more accurate parts with less waste.

Conclusion

As new tech trends loom on the horizon, 2023 looks set to be a defining year for industrial operations. From the exchange of data to asset tracking, cyber security, digital ethical hacking and more, the entire industrial sphere is preparing for transformation.

To keep up with these advancements, digital transformation has become essential for industries. As such, the best strategy is to welcome these changes early, to be fully prepared when 2023 arrives.

For organizations wishing to start this journey, OrangeMantra can provide expert guidance and assistance. Reach out to us and let us help your business to stay ahead of the curve.

FAQs

1. What are top tech trends in 2023 to leverage?

IoT, AI, and Digital Twin are top three technology trends you can leverage to boost your business productivity.

2. How can I hire developers to complete digital transformation with emerging technologies?

Leverage IT staff augmentation to hire dedicated developers to achieve complete digital transformation to improve processes and operations.

3. What are top companies to create custom business solutions with emerging technologies?

Connect with us to discuss the limitless possibilities of customizing your solution using modern tech like IoT, AI, ML and more.