Here’s what you will learn:

In recent years, Artificial Intelligence (AI) has emerged as a transformative force, with AI solutions for manufacturing reshaping the production industry. AI refers to the development of computers that are capable of performing a wide range of tasks that normally require human intelligence, together with data, making selections, and solving complicated project-related issues.

In the manufacturing industry, AI technology implications are targeted to optimize tactics, reduce operational costs, and, in the end, revolutionize how products are manufactured.

Manufacturers are rapidly incorporating AI-driven solutions to make the business’s internal processes smoother and stay relevant in the global competition. From predictive maintenance AI and AI-driven quality control to AI-powered supply chain optimization to procedure automation, AI is proving to be the manufacturing industry, permitting groups to streamline operations, increase efficiency, and meet the needs of a more dynamic and client-centric manufacturing landscape.

This blog will guide you through various use cases and implications of AI in the manufacturing industry, showcasing its ability to force innovation and productivity within the industry.

Therefore, to sum it up, some crucial factors need to be followed:

- The inventory management system

- Real-time visibility of the manufacturing procedure

- A single source of almost every kind of production data.

- Remote systems

- Scaling up production capacity

Table of Contents

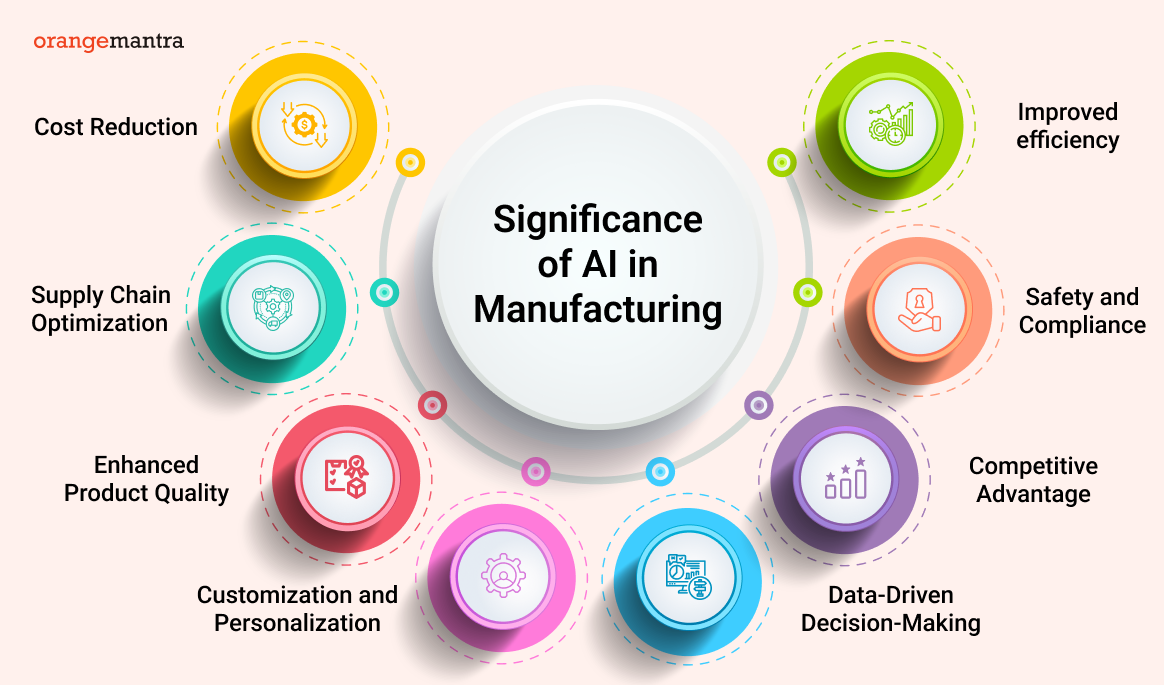

Significance of AI in Manufacturing

The significance of AI in the manufacturing industry is profound. Now, let’s understand this with the explanation of the following points:

1- Improved Efficiency

Smart manufacturing with AI allows systems to optimize production techniques, leading to increased operational performance. This includes automating repetitive duties, decreasing downtime through predictive renovation, and best-tuning manufacturing schedules for maximum productivity. You can hire AI developers for more assistance.

2- Cost Reduction

By minimizing waste, strength intake, and production errors, AI enables producers to cut costs. Predictive maintenance AI, for example, prevents costly breakdowns, at the same time as AI-pushed inventory management minimizes overstocking and understocking. Especially in the IT services for the manufacturing industry, the use of Artificial Intelligence is multifaceted. So, the incorporation of this technology into the IT businesses typically helps in cost reduction and consequently a remarkable growth it.

3- Enhanced Product Quality

AI can perform excellent real-time management with excessive accuracy. Specifically in manufacturing software development, AI has much more effective result-driven contributions. Improved product high-quality and consistency, reducing defects and recollects, which can be costly and destructive to a logo’s recognition.

4- Customization and Personalization

AI permits producers to offer customized products at a scale. Through data analysis and machine learning, corporations can tailor products to individual client alternatives, commencing new marketplace possibilities.

5- Supply Chain Optimization

Artificial Intelligence optimizes the entire supply chain. These AI-powered supply chain systems improve forecasting, from sourcing uncooked materials to handing over completed products. It helps in forecasting, direction optimization, and inventory control, making sure that materials are to be had when wished and reducing lead instances.

6- Safety and Compliance

AI can enhance protection in production by using tracking and responding to capability dangers in real time. It also enables in making sure regulatory compliance by using automating documentation and reporting.

7- Data-Driven Decision-Making

AI processes enormous amounts of information generated in manufacturing, imparting actionable insights for decision-makers. This records-pushed approach allows for non-stop improvement and knowledgeable strategic making plans.

8- Competitive Advantage

Manufacturers adopting AI gain a competitive facet. Those who harness AI technologies can reply more quickly to marketplace modifications, offer progressive merchandise, and preserve better efficiency ranges, positioning themselves as enterprise leaders.

9- Workforce Support

AI and automation can help the team of workers with the aid of managing repetitive or dangerous tasks, permitting human people to pay attention to greater cost-brought and creative aspects of manufacturing.

10- Sustainability

AI-driven optimizations can lead to greater sustainable production practices. By decreasing waste, energy intake, and emissions, AI contributes to environmentally pleasant operations.

AI in manufacturing is an essential transformation revolutionizing business operations, reducing charges, improving product niches, and enabling an extra agile and patron-centric technique. Embracing AI technologies is increasingly essential for manufacturers to stay competitive and thrive in an unexpectedly changing worldwide marketplace.

The Role of AI in Manufacturing: Basics & Implications

The position of AI (Artificial Intelligence) in production is pivotal, as it brings superior skills to the arena, improving efficiency, productiveness, and competitiveness. To recognize this role, at the first step we need to understand what exactly an AI technology is and we can proceed with understanding its implications helping industries across.

Basics of Artificial Intelligence

AI refers to the improvement of computer algorithms that can carry out tasks usually requiring human intelligence. These duties consist of learning from data, spotting patterns, making decisions, solving complex troubles, or natural language. AI can adapt and improve its performance over time through its implications and observing its results.

Role of AI in the Manufacturing Sector

- Predictive Maintenance: AI is used to expect while equipment or machinery is possibly to fail. By analyzing data and sensor readings, AI algorithms can identify signs of imminent breakdowns, permitting manufacturers to carry out upkeep proactively. This reduces unplanned downtime, increases system lifespan, and saves on restoration costs.

- Quality Control: AI-powered image reputation systems can look at merchandise for defects or deviations from nice requirements. Cameras and sensors can capture detailed photographs of objects at the manufacturing line, and AI algorithms can discover errors or irregularities.

- Process Optimization: AI in factory automation and AI in production planning enable smarter optimization of manufacturing techniques or solutions by way of constantly tracking information from sensors. It could make real-time adjustments to parameters such as temperature, strain, and pace to hold the best tiers of performance and product consistency.

- Automation and Robotics: AI-driven robots and automation structures are increasingly used in production. These robots can carry out tricky obligations with precision, pace, and consistency, liberating human people for extra strategic and complicated roles.

- Safety: AI structures decorate protection via detecting and responding to capability hazards, along with anomalies in equipment operation or safety breaches on the store ground.

AI performs an essential role in manufacturing by leveraging facts, automation, and clever choice-making. It enhances performance and competitiveness while allowing manufacturers to conform to evolving client demands and marketplace conditions.

As AI continues to enhance, its packages in production will probably expand, riding further transformation within the enterprise.

Considerable Challenges of AI in Manufacturing

Implementing AI in manufacturing gives several blessings, however, it additionally comes with numerous challenges and worries that want to be addressed.

Here are some of the important thing challenges and issues related to AI adoption within the production enterprise:

1- High Initial Costs

Developing and implementing AI structures may be high-priced. Manufacturers want to put money into hardware, software, professional personnel, and education. Smaller organizations may additionally find it difficult to justify those in advance charges.

2- Data Quality and Availability

AI relies closely on data. Ensuring data efficiency, accuracy, and availability may be tough, particularly when managing legacy systems or when integrating data from numerous sources within the enterprise.

3- Data Security

Manufacturing centers generate and keep sensitive records, together with highbrow belongings and proprietary processes. Protecting this data from cyberattacks and making sure information privacy is a sizable challenge.

4- Lack of AI Talent

There’s a shortage of AI and records technological know-how expertise inside the activity marketplace. Finding and keeping professional AI specialists can be difficult, particularly for smaller producers competing with large tech corporations for skills.

5- Integration with Legacy Systems

Many production centers operate with legacy devices and systems that won’t effortlessly integrate with AI solutions. Retrofitting or upgrading these structures may be complex and pricey.

6- Ethical Concerns

As AI structures become more self-sufficient, ethical considerations increase. Manufacturers want to ensure that AI systems make moral decisions and cling to enterprise standards, mainly in safety-critical applications.

7- Workforce Adaptation

Introducing AI and automation can lead to personnel concerns, which include fears of process displacement. Manufacturers look for a skilled team to establish a smooth transition.

8- Regulatory Compliance

The production enterprise is subject to numerous rules and requirements. Implementing AI may require changes to conform to new rules or adapt current tactics to satisfy unique industry requirements.

9- Complexity of AI Models

AI models, particularly deep mastering models, may be complex and difficult to interpret. Manufacturers need to ensure transparency and understandability in AI choice-making approaches, mainly in critical programs.

10- Scalability

As manufacturing operations grow, scaling AI structures can be tough. Manufacturers ought to bear in mind the way to extend AI implementations efficiently and efficiently as their operations enlarge.

11- Maintenance and Updates

AI systems require ongoing preservation and updates to stay powerful and steady. Manufacturers need to allocate assets for those activities to prevent gadget degradation or vulnerabilities.

Resistance to Change: Employees can be proof to adopting AI and automation technology due to worry of process loss or unfamiliarity with new systems. Change control strategies are important to cope with this undertaking.

12- ROI Uncertainty

Calculating the return on investment (ROI) for AI implementations may be tough, as it may take time to recognize the total benefits. Manufacturers want to set practical expectations and degree overall performance towards clear targets.

When you are addressing these demanding situations, you will automatically start planning for better plans among the IT and other operational teams. It further helps in tracking tasks and efforts that confirm the Artificial Intelligence contributions. Developers effectively navigate these challenges in case they want to discover the ultimate potential of AI operations.

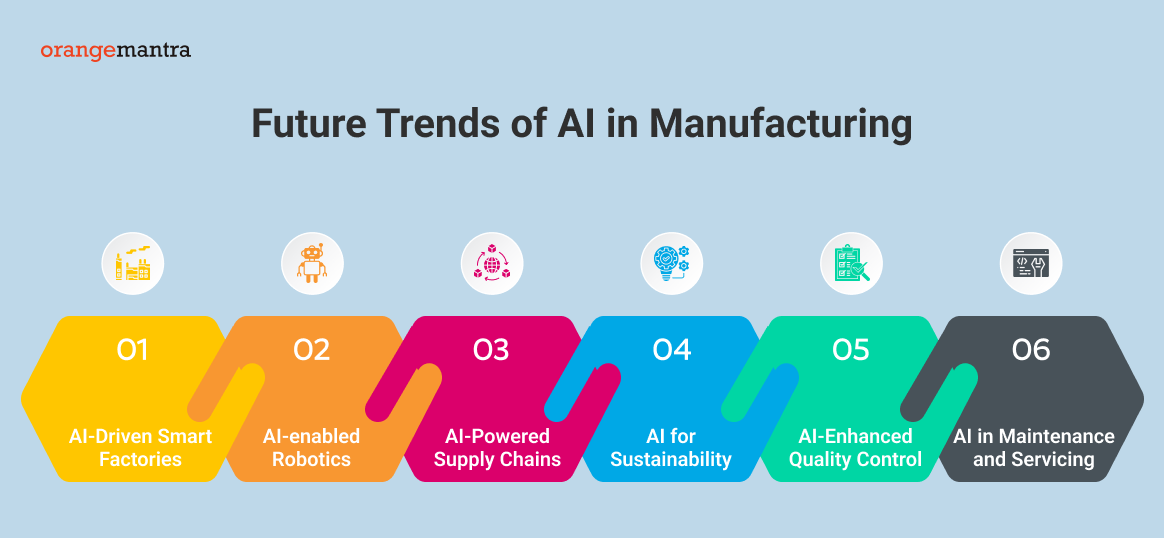

Future Trends of AI in Manufacturing

The destiny of AI in manufacturing promises to bring about several interesting trends that will in addition transform the company.

Here are key trends to consider:

AI-Driven Smart Factories

Smart factories become even smarter with the integration of AI. These factories will have characteristics of interconnected machines, AI structures, and sensors that could display, and optimize, analyze production strategies in real time. Self-optimization manufacturing, predictive maintenance, and agile production could not be unusual.

AI-enabled Robotics

The synergy between robotics and AI will lead to superior and adaptable robots. These robots could have progressed belief, dexterity, and decision-making talents. Cobots (collaborative robots) turn into conventional, operating alongside human beings in production responsibilities.

AI for Sustainability

Manufacturers will use AI to limit their environmental effect. This consists of optimizing electricity intake, decreasing waste, and adopting extra sustainable manufacturing practices. AI will assist businesses meet sustainability goals and adhering to stricter environmental policies.

AI-Powered Supply Chains

Supply chains are becoming wiser and more responsive. AI will play a pivotal role in forecasting, stock management, and logistics optimization. Companies will be better prepared to handle disruptions, lessen lead times, and decorate universal supply chain resilience.

Generative Design

AI-driven generative design equipment will revolutionize product development. Engineers and architects will use AI to create optimized designs based on detailed standards, leading to lighter, more potent, and greater progressive products.

AI in Materials Science

AI will accelerate materials discovery and improvement. Machine learning algorithms will help pick out new substances with perfect properties, improving product performance and sturdiness.

AI-Enhanced Quality Control

Excellent AI-based control systems will keep improving, with the capability to discover even the slightest defects in real-time. This will further enhance product greatly and reduce the need for guided inspection.

AI in Maintenance and Servicing

AI-powered provider and upkeep answers will become extra superior. Predictive maintenance algorithms will not simply expect failures; however, they also advocate ultimate preservation schedules and approaches.

Human-AI Collaboration

The human brain and AI systems will collaborate more closely on the manufacturing unit floor. Workers will use AI tools for selection assistance, troubleshooting, and skill enhancement, leading to better productivity and more secure work environments.

AI in Regulatory Compliance

AI will assist producers in staying compliant with evolving guidelines and pleasant requirements. AI-powered structures can automate compliance reporting and make sure that production techniques adhere to unique enterprise pointers.

AI-Enhanced Customer-Centric Manufacturing

AI will allow producers to provide distinctly customized and customized merchandise at scale. Customers will have an extra say in the design and functions of the goods they buy.

AI in Research and Development

AI will expedite research and development tactics in manufacturing with the aid of simulating experiments, analyzing massive datasets, and accelerating innovation throughout numerous industries.

AI Ethics and Governance

As AI becomes greater integrated into manufacturing, there will be a developing emphasis on AI ethics and governance. Manufacturers will want to set up ethical hints and transparency in AI decision-making.

These positive points indicate that AI development solutions will continue to be a driving force in the back of innovation and competitiveness within the production quarter. Manufacturers that embrace these developments and spend money on AI technologies are in all likelihood to benefit as a great facet in the evolving landscape of AI-powered production.

Top AI Use Cases in Manufacturing

Below are the most practical industrial AI use cases showing how AI reshapes modern production..

1. Smarter Supply Chain Management

Supply chain management is now a very forecast and effective process for AI in manufacturing. Manufacturers can significantly increase demand forecasts, optimize inventory levels, and accelerate shipping routes using historical data, market trends, and logistics patterns. For example, an auto parts company can reduce inventory costs and predict the requirement of spare parts more correctly, while the AI-interested logistics algorithm guarantees early, low-cost delivery. An example of how sophisticated analytics supports decision-making and global accountability is the application of AI at Walmart in supply chain management.

2. Collaborative Robots (Cobots)

Production floors are changing as a result of all-time working robots, or cobots working with human workers. These AI-operated devices use real-time machine learning insights to navigate the complex environment and help in operations such as picking, packing, and assembling. The use of cobots by Amazon has greatly accelerated the supply processes, showing how cooperation between humans and machines improves safety, productivity, and the lack of mistakes in the workplace.

3. AI-Enhanced Warehouse Management

The AI integration warehouse is making operations more intelligent and flexible. Intelligent systems optimize inventions by analyzing market behavior, sales patterns, and existing stocks and cut costs. For example, BMW streamlines handling in its warehouses with AI-powered automatic guided vehicles (AGVs), increasing operational efficiency and inventory accuracy without the need for human interactions.

4. Assembly Line Automation

AI is being used more and more to improve the accuracy, flexibility, and productivity of assembly processes by manufacturers. Through real-time monitoring, the machine learning algorithm manufactures motion adapts to the forecast maintenance requirements and guarantees the quality of the product continuously. AI development services result in clever, sharp, and more reliable manufacturing, as displayed in their assembly lines by the application of AI of Volkswagen AI, which analyzes sensor data to predict the needs of possible repair.

5. Predictive Maintenance

Manufacturers can switch from reactive to active maintenance techniques. Businesses can reduce business expensive downtime by using machine learning and predictive analytics to estimate equipment defects before learning business. In this field, Digital Twin Technology – The virtual copies of physical assets – is an essential tool that enables businesses to monitor the performance of the equipment in real time and estimate the needs of maintenance.

Key Takeaways

AI is having a widespread effect on the production industry, reworking numerous components of production. AI, or Artificial Intelligence, entails computer structures that mimic human intelligence. In manufacturing, AI optimizes methods, complements for pr, and reduces operational expenses.

AI in Manufacturing industry improves performance, reduces expenses, complements high-quality manipulate, and permits customization. It additionally offers blessings in supply chain control, process optimization, and safety.

The blog furnished actual international examples of AI packages in production, together with predictive protection, quality control, supply chain optimization, procedure automation, and more.

Implementing AI in manufacturing comes with challenges like initial prices, first-rate information, and groups of workers variation. Concerns consist of information protection, ethics, and regulatory compliance.

The blog highlighted future developments in AI and manufacturing, which include clever factories, AI-more desirable robotics, sustainability efforts, generative layout, and human-AI collaboration.

AI is reshaping production, providing extraordinary capacity for innovation and competitiveness within the industry. These key points provide a comprehensive assessment of the way AI is revolutionizing the production zone and its ability to continue driving improvements in destiny.

FAQs

1. What role does AI play in manufacturing?

Manufacturers can now offer mass adaptation, which allows them to adapt products for each customer’s preferences without renouncing the speed of production. Businesses can modify the design rapidly in response to the real -time customer response by including AI in the design process.

2. What role does AI play in manufacturing?

Manufacturers can now offer massive adaptation to AI, which allows them to adapt products for each customer’s preferences without compromising the speed of production. Businesses can modify the design rapidly in response to the real-time customer responses by including AI in the design process.

3. How can manufacturing production planning be enhanced by AI?

AI improves production planning’s demand forecasting by more precisely examining past data and market trends. It produces flexible plans that adjust to changes by optimizing Master Production Scheduling (MPS) by taking into account several variables, including production limits, resource availability, and demand projections.

4. What advantages does AI offer the manufacturing industry?

Rapid prototyping makes it simpler to identify design flaws early in the product development process, while AI-assisted quality control helps manufacturers decrease the number of products with defects and provides real-time feedback for root cause analysis.

5. What is the price of producing AI?

AI software development can cost anywhere from $10,000 for a basic feature or solution to $200,000 or more for the complicated tech portion alone. AI can therefore be reasonably priced. The cost of developing AI is influenced by numerous factors, though.