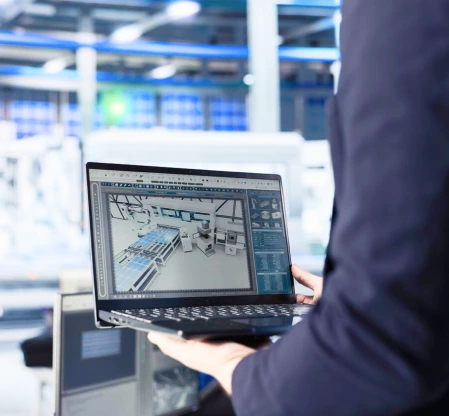

Computer Vision for Manufacturing

Go beyond cameras and screens and transform your factory operations with cutting-edge computer vision in manufacturing. Our intelligent vision systems are designed to enhance speed, precision, and productivity across your production line.

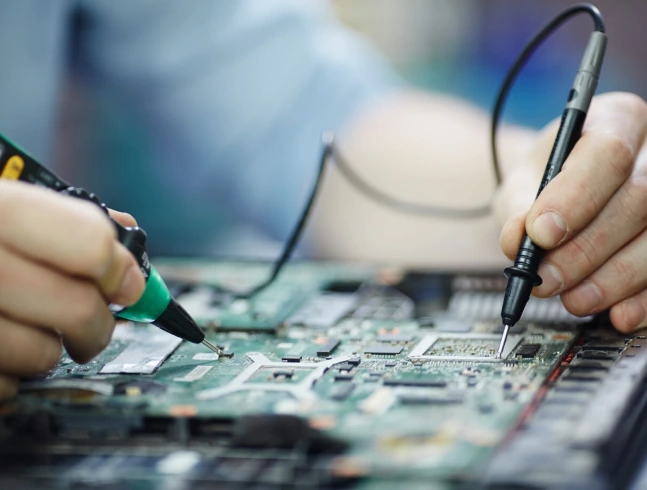

Higher First-Pass Yield

Smarter Inspections

Safer Workspaces

Lower downtime

Faster Output